Introduction

Manufacturers don’t become autonomous by adding a single tool—they get there by connecting assets, contextualizing data, and removing slow, manual steps. With platforms and controls from partners like Rockwell Automation—from edge-connected assets to plant-wide analytics—operations can see what’s happening across sites in real time. That visibility lets AI move from describing problems to anticipating them and recommending action. It’s the shift from reactive firefighting to scalable, self-governing systems—where equipment, lines, and teams work from the same, trusted data foundation.

Why Real-Time Visibility Matters (and Manual Lag Doesn’t)

Connected assets beat clipboards. Sensor streams and machine logs replace delayed manual collection—accelerated by Rockwell Automation’s connected control and data layer.

Context turns data into decisions. When maintenance history, alarms, and production targets are linked (e.g., via Rockwell Automation’s plant analytics and MES capabilities), root causes surface fast.

Scalable operations. A single data model across sites removes silos, enabling consistent KPIs and best-practice rollouts that can be standardized on Rockwell Automation architectures.

The Industrial AI Maturity Path

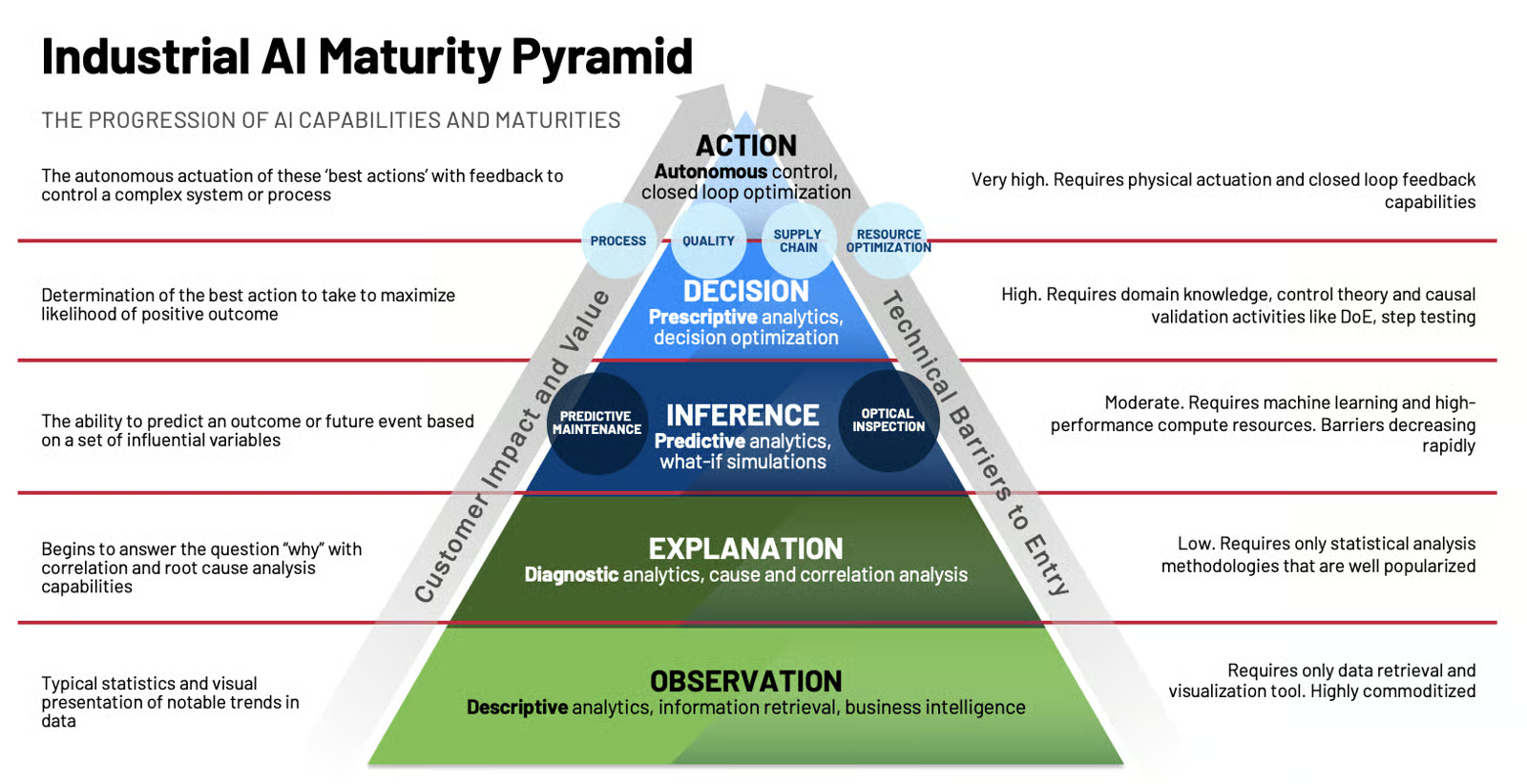

Think of autonomy as a climb:

Observe & Visualize: Unified data, live dashboards (Rockwell Automation dashboards at the line, cell, and plant level).

Explain & Predict: Trend analysis, anomaly detection, “why it failed” insights.

Prescribe & Orchestrate: Decision support, recommended set-point changes, workflow triggers integrated with controls.

Autonomous Operations: Closed-loop control that adapts to changing conditions with minimal human intervention.

Each step blends technology with change management—governance, skills, and new ways of working—often enabled by Rockwell Automation’s combined control + information stack.

Asset Monitoring: Find Downtime Root Causes

Effective asset monitoring is the entry point from “seeing” to “understanding.”

Trend what matters. Tie sensor patterns, alarms, and work-orders together to pinpoint failure modes—with Rockwell Automation connectivity simplifying data capture from PLCs and drives.

Compare like-for-like. Benchmark similar equipment across plants to spot reliability gaps and copy what works.

Schedule proactively. Move from calendar-based to condition-based interventions that extend asset life and reduce cost.

Result: Fewer surprises, faster MTTR, and smarter spares usage—especially when asset data is natively integrated with Rockwell Automation controls and diagnostics.

Quality Control: Predict Issues Before They Ship

High quality keeps customers and regulators happy—and AI helps you stay ahead of variation.

Detect & correct deviations. Flag drift early and recommend adjustments before defects escalate; integrate with Rockwell Automation control loops for faster responses.

Automate inspections. Use vision and pattern recognition to scale consistent checks on high-speed lines.

Guard your inputs. Monitor incoming material quality to reduce downstream scrap.

Result: Less rework and waste, tighter yields, and confidence that every batch meets spec. (Rockwell Automation has showcased this approach in electronics assembly and other discrete/process environments.)

What This Means For Your Plant (South Africa & Beyond)

Standardize data across sites in Gauteng, KZN, Western Cape—then scale best practices quickly on a common Rockwell Automation backbone.

Upskill teams to interpret AI signals and act fast, even as systems do more of the heavy lifting.

Prioritize use cases with quick ROI: critical assets and high-scrap processes.

Call to Action

Ready to replace blind spots with actionable insight? Staro helps manufacturers connect assets, contextualize data, and deploy AI—leveraging Rockwell Automation technologies—to improve uptime and quality. That’s step one on the road to autonomy.

BUSINESS UNITS

Process Control Systems (PCS)

- Programmable Logic Controllers (PLC’s)

- Visualization (HMI and SCADA Systems)

- Software Standards (Abnormal Situation Management)

- Data Historian

- Remote Operating Centres

- Safety Control Systems

Electrical Systems (ES)

- Distribution and Motor Control Centres (MCC’s)

- Intelligent Motor Control

- Advanced Variable Speed Drive Systems

Industrial Information

& Communication

Technology (IICT)

- Industrial Ethernet Networks

- Remote Connectivity

- Cyber Security

- IT Virtualisation

- Manufacturing Execution Systems (MES)

- CMMS

We offer peace of mind project execution knowing that our activities are accredited by ISO9001:2015 Certification and a 5 star NOSA safety certification. This ensures that we maintain a high level of quality assurance and adhere to rigorous Occupational Health and Safety standards during project delivery.

SERVICES

Professional services include each phase of the project lifecycle:

Project management

STARO Integration manages every project with a comprehensive set of tools based on the PMBOK Project Management Standards.

Basic design

STARO Integration has over 25 years’ experience and our experienced engineering team works closely with the customer to understand the initial scope of work for a project and propose a high-level view of the system requirements.

Detailed hardware design

STARO Integration performs the Detailed Hardware Design in line with industry-, OEM- and Quality standards combined with our 25 years of industry knowledge. This is done with continuous client reviews and approval cycles.

Detailed software design

STARO Integration utilise our inhouse software standards as a baseline and with the client determine the standards to be utilised. The Control System Software is then developed utilizing these proven Software standards resulting in a consistent, correct, maintainable control system.

Design drawings

STARO Integration provides Design and Drawing services for instrumentation, field devices and electrical equipment. These drawings including layout, installation, wiring, junction boxes, and cable routing.

Network design

STARO Integration designs according to industry standards as well as vendor specific networks for distributing controllers, I/O, data servers, and operator stations.

Simulation and Factory Acceptance Testing

a FAT plan with checklists tests every loop and HMI/SCADA screen against the Software Design Specification. Quality of workmanship is reviewed against the Quality Assurance check sheets and a punch list of items are resolved before shipping the system.

Site Acceptance Testing and Start-up

After the control system and all the I/O have been installed and commissioned, STARO Integration works with the client to supply the Site Acceptance Testing in accordance with the SAT plan. Site Acceptance Testing proves that the supplied system, including the control logic and operator stations, is interfaced to the field I/O correctly and performs in accordance with the functional design specification.

Training services

STARO Integration can offer either OEM specific training or training specific to a control system project.

Maintenance and support

STARO Integration offers qualified engineers to support the customers installed Control System.

A Service Level Agreement (SLA) makes pre-designated engineers available for pre-planned work or for short notice call outs.

Lifecycle management

STARO Integration can provide the client with strategies, alternatives, and estimates for upgrades and migrations.

Download documents

Download documents

HEAD OFFICE

17 Venus Street, Sasolburg, 1947

+27 (0)16 971 3333

SECUNDA BRANCH

16 Steenkamp Street, Secunda, 2302

+27 (0)17 634 7011

sales@staro.co.za

PROUDLY DESIGNED AND BUILT BY BUNNYPANTS GRAPHIC & WEB DESIGN STUDIO | 2023